The pandemic lockdown of mines, factories and transportation caused a huge plunge in industrial demand in early 2021.

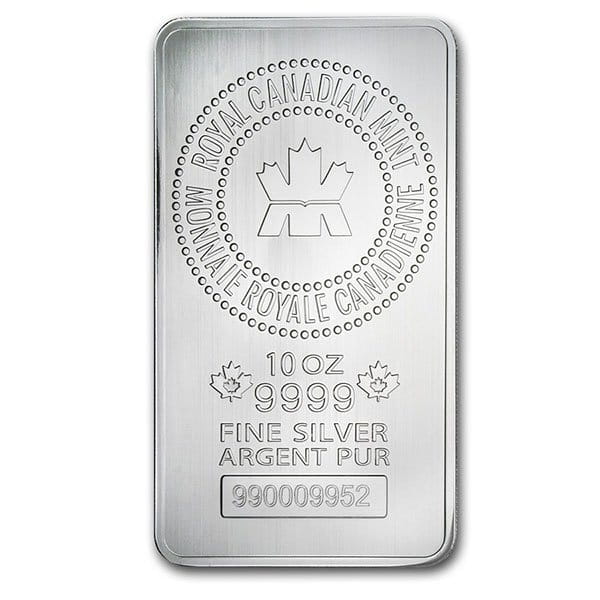

The lockdown also led investors to buy silver bullion coins in record amounts. The last two years have set new sales records for silver and gold bullion coins at both the Royal Mint and Perth Mint.

The use of silver in the manufacturing of consumer electronics, electric vehicles and solar panels has hit record highs.

The solar and electric vehicle industries are largely driven by billions of dollars of government funding and incentives. Even with the economy is a downward spiral it’s likely that subsidies and other funding for solar and green energy projects will continue. Green energy initiatives will continue to drive demand for silver for at least the next decade.

The President’s climate agenda has a goal that 50% of all new car sales by 2030 should electric vehicles.

Conservative estimates place 18 to 26 million new electric vehicles on the roads over the next seven years. With each having slightly more than one troy ounce of silver, that adds up to 20 to 30 million troy ounces or roughly 900 tons of silver needed.

A recent study from Australia believes that new solar panel manufacturing will deplete the world’s current silver stockpile by 2050.

Typical cell phone only small amounts of precious metals, roughly 1/35 gram of gold and a 0.34 gram of silver. Sales of smartphones are projected to reach 1.49 billion units by 2026, which will consume 50.155 tons of pure gold and a whopping 500 tons of silver.

The majority of silver that is pulled from the ground results as a byproduct from mining other metals. As domestic mining of related metals has remained steady over the last decade, domestic silver production typically averages roughly 1,082 tons per year.

Major automakers including Tesla and General Motors have announced large cash investments in mining.

Industry analysts from both industries are speculating this to be a huge strategic advantage given the push to reduce dependence on fossil fuels.

Technology from the Boring Company already exists that could easily be applied to upend operations in the mining industry.

Their latest tunnel boring machine, named PrufRock, is capable of digging a one mile long, 12 foot diameter tunnel about a week.

Applying this to existing mining operations and adopting new methods of mining precious metals could lead to drastically improved operating margins and reduction in fuel consumption in addition to significantly reducing the environmental damage and long term effects caused by the stripping overburden to reach paydirt.

Producing rare earth metals and minerals to meet the needs for EV batteries would be an excellent application of Boring Machine technology to the mining industry. Adapting the machines to dig and sort through deposits is also a way to help eliminate the harsh conditions faced by workers in cobalt mines throughout the world.

Despite record high inflation spot prices have stayed relatively low but volatile.

Consumer Drivers of Silver Demand

Solar panels manufacturing consumes roughly 10 grams of silver per square meter that generate around 200 watts.

Estimates from the Silver Institute show that each hybrid vehicle has 18-34 grams, while a full-electric battery vehicle has 25-50 grams.

Each iPhone has 0.034g of gold (Au), 0.34g of silver (Ag) and 0.015 of palladium (Pl).

Apple sold 240 million units in 2021, consuming:

- 8 tons of gold,

- 81.6 tons of silver

- and 3.6 tons of palladium